Your cart is currently empty!

3D Printing and STEAM Education

Back to: Full STEAM Ahead

Overview

3D printing, or additive manufacturing, creates three-dimensional objects from a digital file by layering materials. This technology has revolutionized manufacturing, design, prototyping, and various other industries by enabling the rapid creation of complex shapes and custom designs that were previously impossible or highly costly to produce.

How 3D Printing Works

- Designing the Model:

- The process begins with creating a 3D model using Computer-Aided Design (CAD) software, such as Tinkercad. This digital model serves as a blueprint for the object to be printed.

- Alternatively, existing objects can be scanned using 3D scanners to create a digital model.

- Slicing the Model:

- The 3D model is then sliced into thin, horizontal layers using slicing software. This step converts the model into instructions that the 3D printer can follow.

- The slicing software also determines the path the printer’s extruder will take and other settings, such as layer thickness, infill, and support structures.

- Printing the Object:

- The 3D printer builds the object layer by layer. Depending on the technology used, materials like plastic, metal, resin, or incredibly biological cells are deposited and fused.

- Standard 3D printing technologies include Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).

- Post-Processing:

- Once the printing is complete, the object may require post-processing, such as removing support structures, sanding, or painting to achieve the desired finish.

So let’s see 3D Printing at Work

Advantages of 3D Printing

- Customization: 3D printing allows for creating custom designs tailored to individual needs, whether for medical devices, consumer products, or personalized art.

- Rapid prototyping allows designers and engineers to iterate their designs quickly, reducing the time and cost associated with traditional prototyping methods.

- Complexity: 3D printing can produce highly complex geometries that would be impossible to create with traditional manufacturing techniques.

- Reduced Waste: Additive manufacturing typically produces less material waste than subtractive manufacturing, making it more environmentally friendly.

Challenges and Limitations

- Material Limitations: While the range of materials available for 3D printing is expanding, it is still limited compared to traditional manufacturing methods.

- Print Speed: 3D printing can be slower than traditional manufacturing methods, particularly for large-scale production.

- Post-Processing: Many 3D-printed objects require additional finishing work, which can add time and cost.

- Cost of Equipment: High-end 3D printers and materials can be expensive, limiting access for some users.

Types of 3D Printing Technologies

- Fused Deposition Modeling (FDM):

- The most common and accessible type of 3D printing, FDM, involves extruding heated thermoplastic filament through a nozzle to create layers.

- Stereolithography (SLA):

- SLA uses a laser to cure liquid resin into solid layers. It is known for producing highly detailed and smooth objects.

- Selective Laser Sintering (SLS):

- SLS uses a laser to sinter powdered material (such as nylon or metal) into solid structures. It is often used for industrial applications because it creates durable, functional parts.

- Digital Light Processing (DLP):

- It is similar to SLA but uses a digital projector screen to flash an entire layer of light simultaneously, curing the resin faster.

- Binder Jetting:

- This technique involves depositing a binding agent onto a powder bed to create layers. It is often used for full-color prints or metal parts.

Most Common Types of Materials

Each material has different properties, making it suitable for specific applications depending on strength, flexibility, heat resistance, and cost considerations.

1. FDM/FFF (Fused Deposition Modeling / Fused Filament Fabrication) Materials:

PLA (Polylactic Acid) – By far the most common for STEAM Education

- Properties: Nontoxic, Biodegradable, easy to print, low warping, low-temperature printing.

- Applications: Prototyping, educational purposes, decorative items, low-strength applications.

- Pros: Environmentally friendly, low cost, easy to use for beginners.

- Cons: Brittle, not heat-resistant, limited strength.

2. ABS (Acrylonitrile Butadiene Styrene)

- Properties: Strong, durable, heat-resistant, higher printing temperature.

- Applications: Mechanical parts, automotive parts, and enclosures.

- Pros: Tough and durable, better heat resistance than PLA.

- Cons: Requires a heated bed, prone to warping, emits potentially toxic fumes when printing (requires proper ventilation)

More FDM/FFF Material Types

PETG (Polyethylene Terephthalate Glycol-modified)

- Properties: Strong, flexible, chemical-resistant, food-safe.

- Applications: Food containers, mechanical parts, outdoor products.

- Pros: Good balance between strength, flexibility, and ease of printing.

- Cons: Prone to stringing, more difficult to print than PLA.

TPU (Thermoplastic Polyurethane)

- Properties: Flexible, elastic, durable, impact-resistant.

- Applications: Phone cases, flexible parts, wearables, seals.

- Pros: High elasticity and impact resistance.

- Cons: More difficult to print due to its flexibility, slow printing speeds.

Nylon (Polyamide)

- Properties: Strong, durable, abrasion-resistant, flexible.

- Applications: Gears, mechanical parts, functional prototypes.

- Pros: High strength and durability, wear-resistant.

- Cons: Absorbs moisture from the air, requires higher printing temperatures.

Wood-Filled Filament

- Properties: Mixture of PLA and wood fibers, produces wood-like prints.

- Applications: Decorative items, art, and models.

- Pros: Wood-like finish, easy post-processing (sanding, staining).

- Cons: Brittle, can cause nozzle clogs if not properly maintained.

Carbon Fiber-Reinforced Filament

Cons: Abrasive, requires a hardened steel nozzle to avoid wear.

Properties: Composite of PLA, PETG, or Nylon with carbon fibers for extra strength.

Applications: High-strength parts, lightweight structures.

Pros: Lightweight and strong.

3. Metal 3D Printing (DMLS/SLM – Direct Metal Laser Sintering/Selective Laser Melting) Materials:

Stainless Steel

- Properties: Strong, durable, and corrosion-resistant.

- Applications: Aerospace, medical implants, automotive, tooling.

- Pros: High strength and corrosion resistance.

- Cons: Expensive, requires advanced 3D printing technology.

Titanium

- Properties: Lightweight, strong, corrosion-resistant.

- Applications: Aerospace, medical, and high-performance engineering parts.

- Pros: Excellent strength-to-weight ratio, biocompatible.

- Cons: Very expensive and difficult to print.

Aluminum

- Properties: Lightweight, strong, corrosion-resistant, heat-conductive.

- Applications: Automotive, aerospace, and consumer products.

- Pros: Lightweight, good thermal properties.

- Cons: Expensive and more difficult to process.

Applications of 3D Printing

- Prototyping:

- 3D printing is widely used in product development to create prototypes quickly and cost-effectively. Designers and engineers can test form, fit, and function before moving to full-scale production.

- Manufacturing:

- In manufacturing, 3D printing allows for producing complex parts that would be difficult or impossible to create using traditional methods. It also enables customization and small-batch production.

- Healthcare:

- 3D printing creates custom prosthetics, implants, and surgical guides. It also plays a role in bioprinting, where cells are printed to create tissue-like structures.

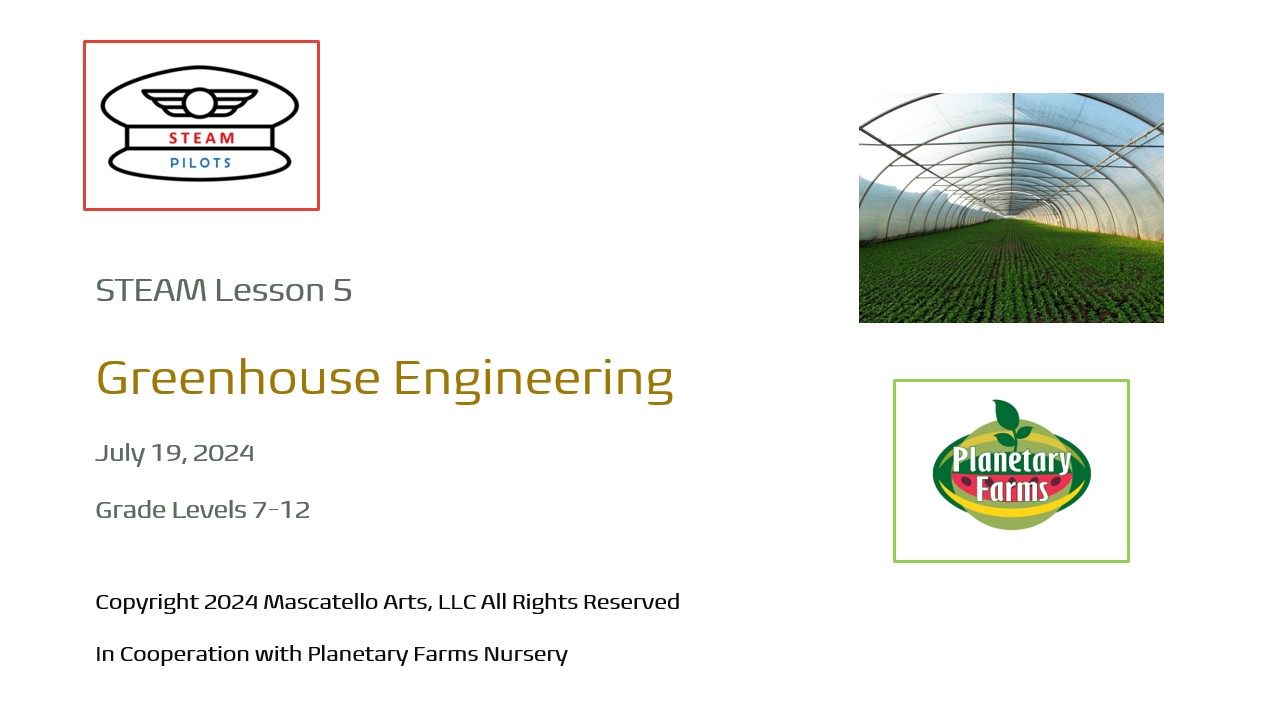

- Education:

- Educational institutions use 3D printing to enhance learning in STEAM (Science, Technology, Engineering, Art, and Mathematics) subjects. This allows students to bring their designs to life and explore engineering concepts hands-on.

- Architecture:

- Architects use 3D printing to create detailed models of buildings and structures, facilitating the visualization of designs and enabling more complex architectural forms.

- Art and Fashion:

- Artists and fashion designers use 3D printing to explore new creative possibilities, producing intricate sculptures, jewelry, and wearable art that would be challenging to make by hand.

Using Tinkercad to Design 3D Models

Tinkercad

- Target Audience: K-12, beginners

- Overview: Tinkercad is a free, web-based, easy-to-use CAD software that introduces students to 3D design. It allows students to create models, circuits, and even simple code blocks for programming.

- Use in STEAM: Ideal for teaching 3D design, basic electronics, and creative thinking. It’s commonly used for integrating art projects with engineering (e.g., designing artistic sculptures or functional objects).

To create an STL file from a JPEG image using Tinkercad, you can follow these steps. Note that Tinkercad doesn’t directly import JPEGs or other image files, but it can work with SVG (vector) files, which you can convert your image into. Here’s a general workflow:

Steps:

- Convert the JPEG to an SVG:

- Tinkercad can import SVG files, but not JPEGs directly. You will need to convert your JPEG into an SVG (Scalable Vector Graphics) format.

- You can use free online tools like:

- Convertio

- ImageMagick

- Inkscape (a vector graphics software, more advanced).

- The conversion process might simplify the image, but you can control settings to get a good result.

- Import the SVG into Tinkercad:

- Log into your Tinkercad account.

- Open a new design or select an existing one.

- On the right side, click on Import.

- In the pop-up window, select Choose File, then upload the SVG file you created from the JPEG.

- Set the size (dimensions) and scale if needed, then click Import.

- Edit the Design:

- Once imported, you can manipulate the shape or design using Tinkercad’s tools. Adjust the height, cut out shapes, or combine it with other elements as needed.

- Export as an STL File:

- After you are satisfied with your 3D design, you can export it as an STL file.

- Click on Export in the top right corner of the interface.

- Choose .STL format from the export options.

- The STL file will be downloaded to your computer.

Notes:

- The quality of the conversion from JPEG to SVG depends heavily on the complexity of the image. Simplified images with clear outlines work best for 3D printing.

- SVG files are 2D by nature, so you may need to extrude the imported shape to give it a 3D appearance before exporting.

By following these steps, you can transform a JPEG image into an STL file for 3D printing using Tinkercad!

Here is a list of other available CAD software programs for STEAM Education

Here is a list of the most popular CAD software used in STEAM (Science, Technology, Engineering, Arts, and Mathematics) education. These platforms are ideal for integrating artistic and creative design with STEM disciplines, making them great tools for both technical and artistic fields in education.

Fusion 360

- Target Audience: High school, college, and professionals

- Overview: Fusion 360 is a powerful cloud-based CAD tool that combines 3D modeling, manufacturing, simulation, and collaboration in one platform. Free for students and educators.

- Use in STEAM: Useful for both artistic design (product design, industrial design) and technical engineering (mechanical and simulation). It’s a great tool for students working on both functional and aesthetic design projects.

SketchUp

- Target Audience: K-12, higher education, and beginners

- Overview: SketchUp is known for its intuitive interface and is popular for architectural design, product modeling, and artistic 3D design. It has both a free version and a more advanced paid version.

- Use in STEAM: Widely used for both architectural and artistic design projects. Teachers can combine elements of engineering, math (geometry), and art in their lessons using SketchUp.

Blender

- Target Audience: High school, university, and advanced students

- Overview: Blender is an open-source, professional-grade software used for 3D modeling, animation, and visual effects. It’s free and widely used in both technical fields and digital arts.

- Use in STEAM: Perfect for combining art and technology by teaching 3D animation, sculpting, video game development, and even scientific visualizations. It can bridge the gap between art and engineering.

Onshape

- Target Audience: High school, university, and educators

- Overview: Onshape is a cloud-based CAD tool that enables real-time collaboration. It is widely used for engineering design but can also support creative design projects.

- Use in STEAM: Ideal for collaborative projects that merge technical and artistic elements. Students can work together on product designs, mechanical devices, or even artistic creations in real-time.

Autodesk Maya

- Target Audience: High school, university, and professionals

- Overview: Maya is a high-end software used for 3D modeling, animation, and visual effects, particularly in the film and gaming industries. Autodesk offers free educational licenses for students.

- Use in STEAM: Used for teaching 3D animation, game design, and digital art, with applications in math (geometry), physics (simulations), and engineering.

SolidWorks (Student Edition)

- Target Audience: High school, university, and professionals

- Overview: SolidWorks is widely used in engineering and product design fields. It offers a range of powerful tools for 3D design, simulation, and rendering.

- Use in STEAM: Excellent for technical projects, but its built-in rendering and artistic tools also allow students to explore product aesthetics and design, blending creativity with engineering.

FreeCAD

- Target Audience: High school, university, and hobbyists

- Overview: FreeCAD is an open-source parametric 3D modeler. It’s highly customizable and useful for mechanical design and engineering.

- Use in STEAM: In addition to technical projects, FreeCAD can be used for artistic designs, allowing students to explore artistic and engineering concepts simultaneously.

AutoCAD (Student Version)

- Target Audience: High school, university, and professionals

- Overview: AutoCAD is a professional software used for 2D and 3D drafting and modeling. It has a student version with all the features of the professional software.

- Use in STEAM: Useful for both precise technical drawings (architecture, engineering) and creative design (interior design, artistic layout). Students can explore artistic compositions with mathematical precision.

ZBrush

- Target Audience: High school, university, and professionals

- Overview: ZBrush is a digital sculpting tool widely used for creating detailed 3D models. It’s popular in animation, game design, and digital art.

- Use in STEAM: Ideal for teaching artistic modeling and sculpture, while incorporating math and geometry through the manipulation of complex forms and structures.

Inventor (Autodesk)

- Target Audience: High school, university, and professionals

- Overview: Autodesk Inventor is used for 3D mechanical design, simulation, and manufacturing. It offers powerful modeling tools but also includes creative rendering and presentation capabilities.

- Use in STEAM: While geared toward technical disciplines, Inventor allows students to explore the aesthetic aspects of product design, merging engineering and creativity.

These tools are used in STEAM education to bridge the gap between artistic creativity and technical precision. They encourage students to think creatively while applying mathematical, scientific, and engineering principles, making them well-suited for holistic learning experiences in the classroom.

Popular 3D Printer Brands

Makerbot

MakerBot strongly advocates incorporating 3D printing into education, particularly in STEAM (Science, Technology, Engineering, Art, Mathematics) programs. The company provides resources and lesson plans integrating 3D printing into curricula, allowing students to design and create models that bring theoretical concepts to life. MakerBot offers specialized products and support for educators, including:

- MakerBot Certification: Training programs that teach educators and students how to use 3D printers effectively in an academic setting.

- MakerBot Educators Guidebook: A comprehensive guide with lesson plans, tips, and ideas for integrating 3D printing into classrooms.

MakerBot Educator Guide

Lulzbot

- Popular Model: LulzBot TAZ Workhorse, LulzBot Mini 2

- Type: FDM

- Overview: LulzBot is known for its open-source 3D printers with a focus on versatility and modularity, making them popular among makers and educators.

Flashforge

- Popular Model: FlashForge Creator Pro, Adventurer 4

- Type: FDM and Resin

- Overview: FlashForge is known for its wide range of 3D printers, catering to both hobbyists and professionals. Their printers are often praised for ease of use and solid build quality.

Future of 3D Printing

The future of 3D printing is promising, with advancements in materials, speed, and scale expected to drive broader adoption across industries. Potential developments include:

- Bioprinting: Advancements in bioprinting may lead to the ability to print entire organs for transplantation. In the mean time, here is a fascinating video about 3D Printing of bones – yes BONES.

- Now See what NASA is up to in this Science Fiction-like technology – https://www.nasa.gov/missions/station/iss-research/3d-bioprinting/#:~:text=Biological%20printing%20or%20bioprinting%20uses,create%20entire%20organs%20for%20transplants.

- Construction: Large-scale 3D printing could revolutionize construction, enabling the printing of entire buildings on-site.

- Sustainable Manufacturing: As technology advances, 3D printing could play a key role in sustainable manufacturing practices, reducing waste and enabling local production.

3D printing continues to evolve, offering exciting opportunities for innovation and creativity across various fields. As technology becomes more accessible, it is likely to have an even more significant impact on how we design, manufacture, and interact with the world around us.